Customized ED and EDBM Stack Solutions: Tailored for Your Application Needs

- Sep 2, 2025

- 2 min read

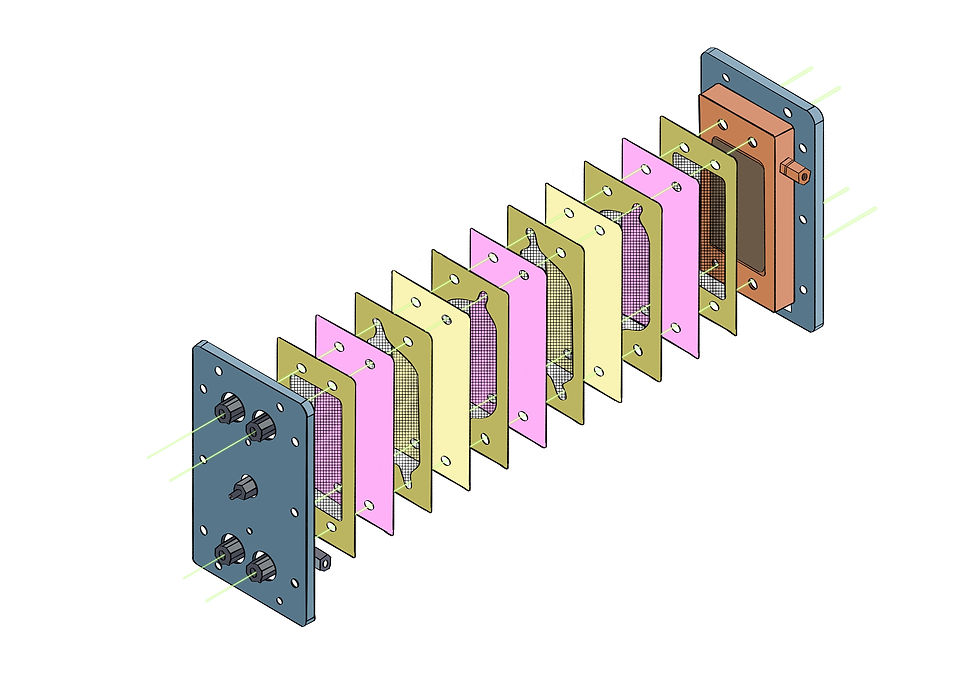

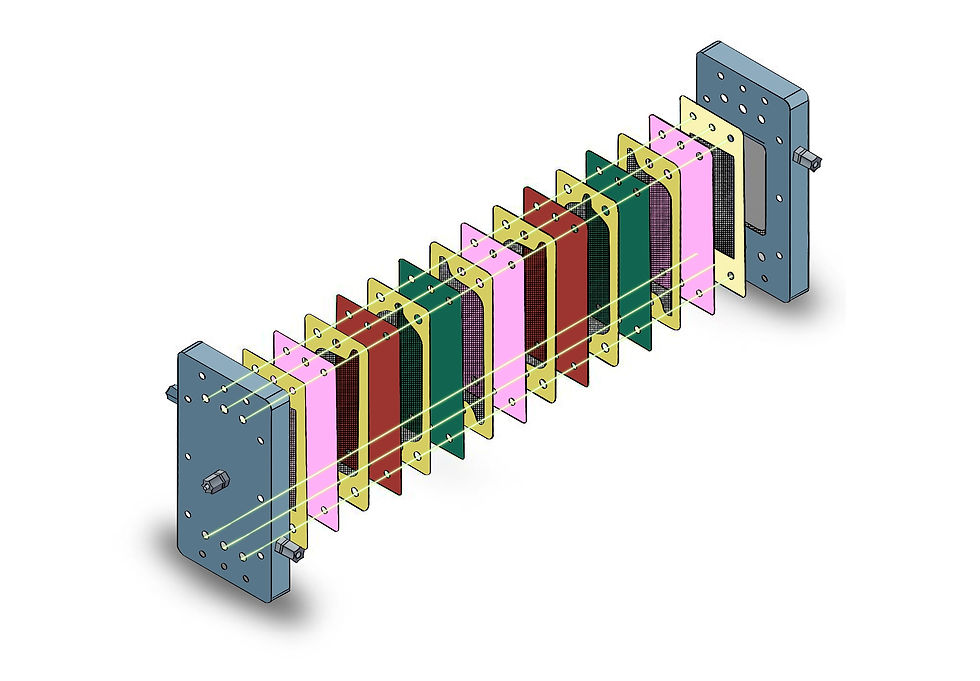

At YASA ET, we understand that every project has its own unique requirements when it comes to desalination, concentration, or chemical production. That’s why we offer customized Electrodialysis (ED) and Electrodialysis with Bipolar Membranes (EDBM) stacks, designed to meet specific technical and commercial needs.

Why Choose Customized Stacks?

Feed Water Variability: From brackish water to high-salinity brine (20,000–150,000 ppm), each application requires careful membrane selection and stack design.

Target Products: Whether your goal is to reduce total dissolved solids (TDS) in water (ED) or produce valuable acid/alkali directly from salts (EDBM), stack configuration plays a key role.

Scale & Capacity: From laboratory-scale modules (10–20 cell pairs) for R&D, to industrial stacks (>100 cell pairs) for continuous production, customization ensures efficiency at any scale.

Chemical Resistance: Different projects involve different solutions (NaCl, Na₂SO₄, organic salts, etc.). Selecting the right membrane type, thickness, and spacer design guarantees stability and longer service life.

Typical Customization Options

Membrane size: From compact 10×10 cm test cells up to 550 mm wide industrial membranes.

Number of cell pairs: Flexible (5–200+) depending on voltage and capacity requirements.

Spacer gap: Adjustable (0.5–1.0 mm) to balance pressure drop, flow velocity, and scaling tendency.

Electrode materials: Titanium with MMO or noble metal coatings, tailored for durability.

Flow configuration: Optimized for desalination, concentration, or acid/alkali production.

Applications of Customized ED/EDBM

Water Desalination: Brackish water, seawater concentration, and produced water treatment.

Chemical Recovery: Acid recovery from pickling liquor, alkali recycling, and sulfate removal.

Green Chemical Production: Direct generation of HCl, NaOH, and H₂SO₄ without chlorine gas by-products.

Laboratory & Pilot Testing: Modular stacks for universities, R&D centers, and pilot demonstrations.

Why YASA ET?

Over 10 years of expertise in electrodialysis and bipolar electrodialysis.

Proven track record in industrial, pilot, and laboratory systems worldwide.

Ability to design, build, and supply turnkey customized stacks that integrate into your process.

For the right treatment system, you need the right expertise.

For more information about our zero liquid discharge systems, kindly get in touch at:

🌐 www.yasa.ltd(EN)

🌐 www.yashahuanjing.cn (中文)

📱 +86 136 3643 1077

YASA ET official online store > click here

Comments